Introduction

The global Manufacturing Execution System (MES) market has emerged as one of the most pivotal segments within industrial automation, serving as the backbone for smart manufacturing initiatives. MES software bridges the gap between enterprise-level planning systems and shop-floor control systems, offering real-time visibility, traceability, and optimization of manufacturing processes. As industries face increasing pressure to enhance efficiency, reduce costs, and improve compliance, the adoption of MES solutions is accelerating worldwide.

In today’s competitive environment, where digital transformation, Industry 4.0, and smart factories are redefining production landscapes, MES plays a critical role in ensuring operational excellence. Its ability to improve resource allocation, boost product quality, and provide actionable insights makes it indispensable across diverse industries such as automotive, aerospace, healthcare, and electronics.

This report provides an in-depth analysis of the MES market, exploring key growth drivers, challenges, opportunities, market segmentation, and the competitive landscape. It also highlights future trends and outlook, offering valuable insights for businesses, investors, and policymakers navigating this dynamic industry.

Source - https://www.databridgemarketresearch.com/reports/global-manufacturing-execution-system-mes-market

Market Overview

The Manufacturing Execution System (MES) market refers to software solutions that monitor, track, and document the transformation of raw materials into finished goods in real time. MES sits between Enterprise Resource Planning (ERP) and Supervisory Control and Data Acquisition (SCADA) systems, creating a seamless flow of information across the manufacturing value chain.

Historically, MES was adopted by industries with complex manufacturing processes, such as semiconductors and aerospace. However, in recent years, its application has broadened due to increasing demand for operational transparency, compliance with stringent regulations, and the global push for digitization.

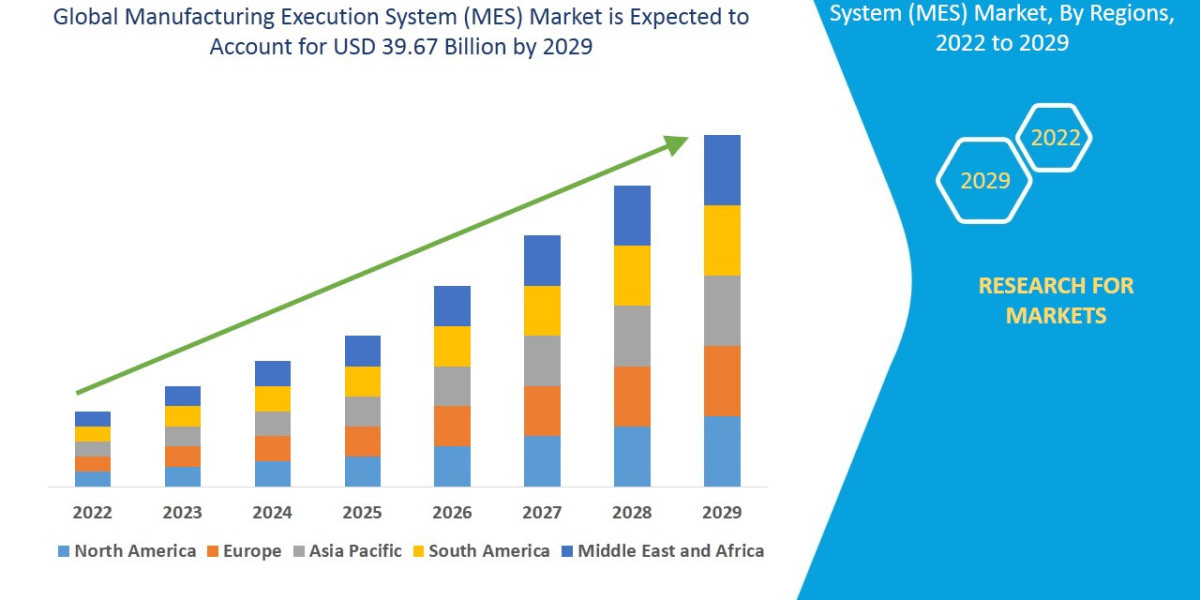

According to industry research, the MES market was valued at around USD 14–15 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8–10% between 2023 and 2030. Factors such as rising adoption of Industrial IoT (IIoT), cloud-based MES solutions, and the expansion of smart factories are fueling this growth. North America currently leads the market, but Asia-Pacific is expected to witness the fastest growth due to rapid industrialization and government-backed digital manufacturing initiatives.

Market Drivers and Opportunities

Several factors are driving the growth of the MES market:

Industry 4.0 and Smart Manufacturing Adoption

With factories shifting towards automation and digitalization, MES plays a critical role in integrating IoT, robotics, and advanced analytics into production processes.Regulatory Compliance and Quality Control

Industries such as pharmaceuticals and food & beverage face stringent regulations. MES provides robust traceability and compliance features, making it essential for ensuring product safety and meeting global standards.Cloud-Based and SaaS Solutions

The rise of cloud technology is making MES more scalable and cost-effective, particularly for small and medium-sized enterprises (SMEs).Growing Focus on Sustainability

MES enables efficient resource utilization and waste reduction, aligning with global sustainability goals and ESG frameworks.

Opportunities ahead:

Integration of MES with artificial intelligence (AI) and machine learning (ML) for predictive analytics.

Adoption of mobile MES applications for real-time decision-making.

Expansion in emerging markets, especially in Asia-Pacific and Latin America, where manufacturers are aggressively modernizing.

Market Challenges and Restraints

Despite its promising outlook, the MES market faces several challenges:

High Implementation Costs

Deploying MES often requires significant upfront investment in hardware, software, and skilled labor, which can deter smaller manufacturers.Integration Complexities

Integrating MES with legacy ERP, SCADA, and PLC systems remains a challenge, leading to longer deployment cycles.Data Security Concerns

With increasing connectivity, cyberattacks on manufacturing systems are a growing concern. MES providers must ensure robust cybersecurity measures.Skill Gaps

The shortage of skilled professionals with expertise in MES implementation and maintenance can slow adoption rates.

If not addressed, these restraints may limit adoption in cost-sensitive and resource-limited industries.

Market Segmentation Analysis

The MES market can be segmented based on product type, deployment mode, end-use industry, and geography.

1. By Product Type

Software: Core MES platforms that provide planning, scheduling, and execution functionalities.

Services: Consulting, integration, training, and support services that complement software deployment.

Software currently dominates the market, while services are expected to see significant growth as enterprises demand customization and integration expertise.

2. By Deployment Mode

On-Premise: Preferred by large enterprises requiring control over data and customization.

Cloud-Based: Rapidly growing segment due to scalability, lower upfront costs, and remote accessibility.

3. By End-Use Industry

Automotive: Adoption driven by complex production lines and the demand for high-quality standards.

Pharmaceuticals & Life Sciences: Strong adoption due to regulatory compliance and traceability needs.

Electronics & Semiconductors: Require high precision and yield optimization.

Food & Beverage, Aerospace, Oil & Gas: Increasing adoption for quality control and operational efficiency.

Pharmaceuticals and automotive sectors are among the most dominant industries in MES adoption.

4. By Geography

North America: Largest market, driven by early adoption of Industry 4.0 and presence of key players.

Europe: Strong focus on sustainability and automation in Germany, France, and the UK.

Asia-Pacific: Fastest-growing region due to industrialization in China, India, South Korea, and Japan.

Latin America & Middle East: Emerging adoption, driven by oil & gas, mining, and energy sectors.

Competitive Landscape

The MES market is highly competitive, with global technology providers and specialized vendors offering innovative solutions.

Key players include:

Siemens AG

Rockwell Automation, Inc.

ABB Ltd.

Emerson Electric Co.

Dassault Systèmes

Honeywell International Inc.

AVEVA Group plc

These companies are focusing on strategic mergers, acquisitions, and partnerships to expand their product portfolios and strengthen their global presence. For example, Siemens continues to invest in integrating MES with its broader Digital Industries portfolio, while Rockwell Automation is advancing cloud-based MES offerings.

Innovation is another differentiator—vendors are embedding AI, machine learning, and IoT capabilities into MES to deliver predictive maintenance, digital twins, and advanced analytics.

Future Outlook and Trends

Looking ahead, the MES market is expected to undergo significant transformation:

Integration with Emerging Technologies

AI-driven MES platforms will enable predictive maintenance, demand forecasting, and enhanced supply chain visibility.Sustainability and Green Manufacturing

MES will play a central role in enabling energy efficiency, waste reduction, and compliance with ESG standards.Cloud and Hybrid Deployments

Cloud-based MES solutions will dominate due to their flexibility and scalability, particularly for SMEs and multinational enterprises.Regional Expansion

Asia-Pacific will emerge as a major growth hub, with government-backed smart manufacturing initiatives in China, Japan, and India.

By 2030, the global MES market could surpass USD 25–30 billion, fueled by technological innovation and widespread adoption across industries.

Conclusion

The Manufacturing Execution System (MES) market is rapidly evolving, driven by Industry 4.0, regulatory compliance, and demand for efficiency and transparency. While challenges such as high implementation costs and integration complexities persist, the opportunities from AI, IoT, and cloud integration are immense.

For manufacturers, MES is no longer a “nice-to-have” but a strategic necessity to remain competitive in the global marketplace. Stakeholders who invest in MES solutions today stand to gain significant advantages in productivity, compliance, and sustainability over the coming decade.

FAQ Section

1. What is the current size of the MES Market?

As of 2022, the global MES market is estimated at USD 14–15 billion and is projected to grow at a CAGR of 8–10% through 2030, reaching over USD 25 billion by the end of the decade.

2. What are the key drivers influencing growth in this market?

The major drivers include Industry 4.0 adoption, demand for real-time production visibility, regulatory compliance requirements, and increasing use of cloud-based MES solutions.

3. Which regions dominate the MES Market?

Currently, North America holds the largest share due to advanced manufacturing ecosystems, while Asia-Pacific is expected to experience the fastest growth because of rapid industrialization and government digitalization programs.

4. Who are the major players in the industry?

Key players include Siemens, Rockwell Automation, ABB, Honeywell, Dassault Systèmes, Emerson, and AVEVA. These companies dominate the market through innovation, partnerships, and acquisitions.

5. What are the latest trends shaping the future of this market?

Key trends include the integration of AI, IoT, and machine learning into MES platforms, growth of cloud-based solutions, focus on sustainability, and adoption of digital twin technology.

6. What challenges could slow down growth in this sector?

High implementation costs, integration complexities, cybersecurity risks, and lack of skilled professionals could restrain market expansion.

7. How can businesses benefit from investing in the MES Market?

By adopting MES, businesses can achieve higher efficiency, better compliance, improved product quality, and real-time visibility into operations, leading to cost savings and competitive advantages.

Browse More Reports:

Global Fleet Management Market

Global Digital Banking Market

Global Perfume Market

Global Pro AV (Audio-Visual) Market

Global Business Process Outsourcing (BPO) Market

Saudi Arabia Fleet Management Market

Global Alcoholic Beverages Market

Global Healthy Snacks Market

India Business Process Outsourcing (BPO) Market

Global Edible Cutlery Market

Global Manufacturing Execution System (MES) Market

Global Veterinary Medicine Market

Europe Business Process Outsourcing (BPO) Market

Global Biofuels Market

Global Craft Beer Market

Global Recreational Vehicle (RV) Awnings Market

Global Shisha Tobacco Market

Global Sports Nutrition Market

Global D-limonene Market

Global Essential Oils Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com